Top 5 reasons why chicks are rejected at the slaughterhouse and what steps to take

Each broiler carcass processed at the slaughterhouse tells a story about the bird’s life on the farm. While poultry farmers often focus on performance metrics such as growth rate, feed conversion ratio (FCR), and general health, it is ultimately during processing that meat quality and hidden health challenges are revealed.

Carcass rejection rates exceeding 2% not only indicate inefficiencies in the production cycle, but also lead to financial losses and potential regulatory concerns in certain markets. In the Netherlands for example, the cost price for raising conventional chickens is approximately €0.94/kg (in 2021 according to LTO.nl). This means that 2% rejections would result in a lost investment of €18.8/MT in broiler production cost, without taking into account lost profit. In Germany (according to the Geflugel jahrbuch, 2025) these costs are similar at approximately €0.90/kg, meaning a loss of €18/MT. By understanding the leading causes of rejection and implementing targeted nutritional and management measures, producers can significantly reduce losses and improve overall flock performance.

Below are five common reasons for carcass rejection and the corresponding strategies to address them effectively.

1. Health-related conditions

Diseases such as polyserositis, synovitis, hepatitis, pericarditis, subcutaneous inflammation, and ornithobacterium rhinotracheale (ORT) are frequently the cause of rejection at the slaughterhouse. However, these diseases are often secondary infections or accelerated due to poor management practices and reduced immunity.

Recommended nutritional and management strategies:

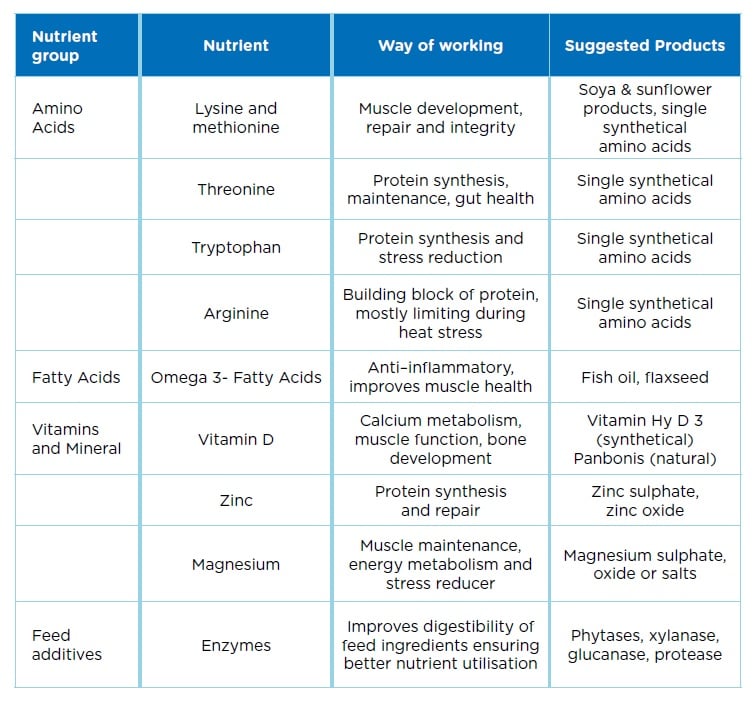

- Good nutrition can strengthen disease resistance by optimising amino acid profiles and including key vitamins.

- Support gut health through well-balanced pre-starter and starter feeds, along with functional additives to improve healthy intestinal microbiota, mucus layer and epithelial integrity.

- Prioritise water hygiene and ensure accessibility to water and feed for all birds.

2. Meat quality defects

Defects such as pale-soft-exudative (PSE) meat, woody breast, white striping, spaghetti meat, and deep pectoral myopathy (DPM) are primarily associated with rapid growth rates driven by genetic selection. These issues compromise processing efficiency and end-product quality.

Recommended nutritional and management strategies:

- Provide balanced levels of digestible lysine, methionine, threonine, and tryptophan to promote healthy muscle development.

- Include omega-3 fatty acids to help reduce inflammation.

- Supplement with antioxidants such as heat-stable vitamin C, vitamin E, and polyphenols to mitigate oxidative stress.

- Supply zinc and magnesium for muscle repair and function.

- Ensure smooth feed transitions to prevent fluctuations in feed intake that may lead to muscle development disorders.

3. Injuries during harvesting and transport

Fractures of the legs or wings often occur due to mechanical injuries related to high stocking densities (> 40 kg/m3) or poor handling during harvesting, loading and transport.

Recommended nutritional and management strategies:

- Enhance skeletal strength by ensuring sufficient levels of vitamin D, calcium, and phosphorus.

- Supplement tryptophan to reduce stress and agitation during catching and transport.

- Review and refine harvesting protocols, especially during high-risk periods such as daylight loading or elevated temperatures.

4. Environment-related issues

Footpad dermatitis, breast blisters, and skin scratches are typically caused by suboptimal housing conditions, including wet litter, poor air movement, and overcrowding.

Recommended nutritional and management strategies:

- Adjust crude protein levels and enhance the quality of raw materials to reduce wet litter.

- Balance electrolytes, such as alternatives to sodium chloride like sodium bicarbonate or sulphate.

- Re-evaluate potassium content of feeds. Especially with high inclusion of soya.

- Improve litter management, optimise ventilation, and prevent temperature fluctuations to minimise risk of dermatitis and skin damage.

5. Chick quality and early nutrition

Early challenges such as poor leg development and flock uniformity are often the result of inadequate early nutrition or stress during hatchery handling and transport.

Recommended nutritional and management strategies:

- Assess chick quality at placement and modify feeding or brooding conditions based on observed needs.

- Offer high-quality, fibre-rich pre-starter feeds to support gut development in the critical first days.

- Monitor early growth trends and adapt feed density and form to support consistent development and prevent muscular strain.

Prevention starts at the farm

Processing-line rejections reflect underlying challenges earlier in the production cycle. By tracking rejection patterns and making data-driven corrective adjustments, producers can improve both economic outcomes and bird welfare, and minimise losses in future flocks. The Koudijs Poultry Approach integrates farm-level assessments, nutritional expertise, and practical support to target the root causes of rejection.

About the author

Jos van Arkel

Poultry Specialist