Selection and validation of the most effective ingredients to de-activate mycotoxins

With a new harvest of fresh raw materials entering the markets, it is a good moment to assess your mycotoxin exposure risk. The likelihood of finding mycotoxins in raw materials used for the production of animal feed is significant. More extreme weather patterns and fluctuations are prime conditions for mycotoxins produced by fungi present in the soil and infecting the cultured crops.

The level of feed contaminated with mycotoxins varies a lot. Based on recent reports, one can make a rough assumption that of the samples testing positive for mycotoxins, 25% of the samples are contaminated with one mycotoxin. The remaining 75% of the positive samples are contaminated with two or more mycotoxins. However, keep in mind that a contamination does not automatically mean that the level of contamination is high enough to induce negative effects in the animals. Unfortunately, it is not always possible to source raw materials with low, or no mycotoxins contamination. In such cases, it is important to establish which mycotoxin(s) are present and at which level. Once this is known, deactivating agents can be added to prevent or reduce the potential damage to the animal.

Selecting the right soldiers to determine a strategy

Koudijs has developed the MycoGuard range with an effective and comprehensive set of products. Here we will share insights on how the different de-activating ingredients were selected and validated to deliver the highest efficacy against frequently occurring mycotoxins.

De-activation of aflatoxins (afla): selecting the best binding bentonite clays

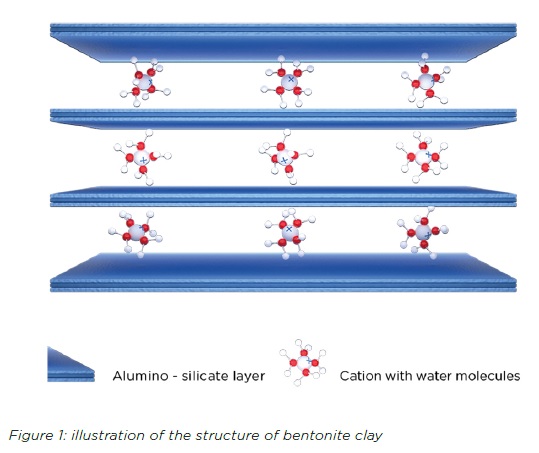

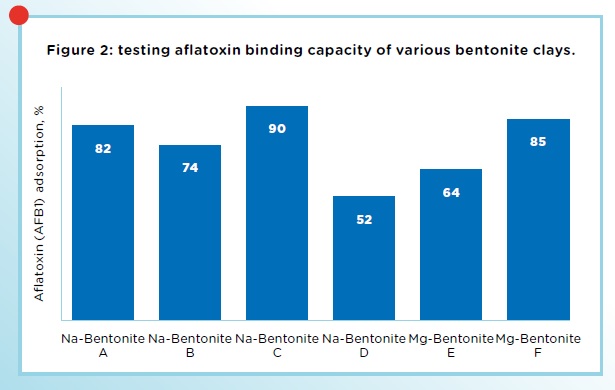

Bentonite clays form part of HSCAS (Hydrated Sodium Calcium Alumino Silicates). The layered structure (see fig. 1) of bentonite clays makes it an ideal compound to bind mycotoxins that have a high polarity and a relatively flat molecular structure and thereby inhibit absorption in the gut. The flatness of AFLA allows it to enter and stay trapped between the bentonite clay layers until it is removed from the animal via feces. Choosing the right bentonite is important because each clay is slightly different from the other and therefore each has different binding capacities. Knowing this, a screening of multiple bentonite clays (see fig 2) resulted in the selection of two bentonite clays. One with high binding strength, while the second has a high binding speed. The sooner AFLA is deactivated, the less damage it can do to animals. MycoGuard Focus consists of a combination of the strongest and the fastest binding bentonite clays. In-vivo trials were conducted to validate the efficacy.

De-activation of zearalenone and ochratoxin

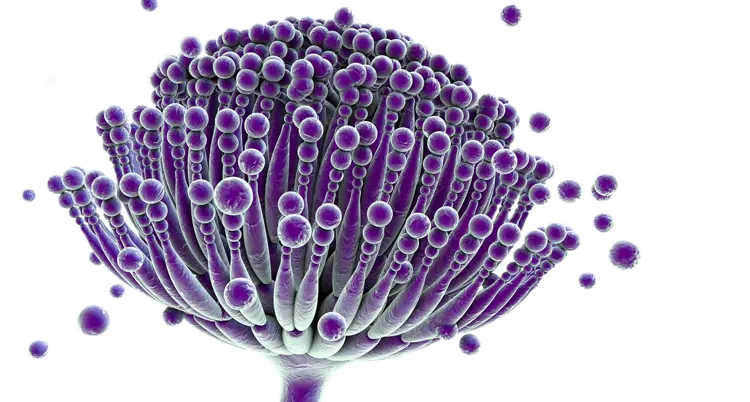

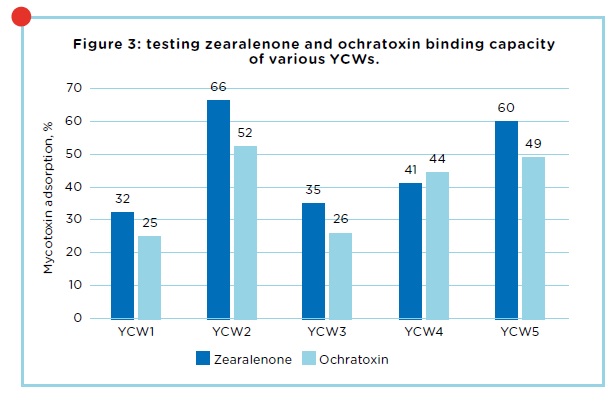

In a similar way, yeast cell wall fractions (YCW) have shown to have a strong binding capacity for mycotoxins that have a more flexible molecular structure. Here too, there is a large variety in strains of yeast, and not all are suitable as mycotoxin binders. Yeast cell walls are built up of a layer of manno-oligosaccharides, followed by a layer of beta-glucans, and finally a thin layer of chitin. The amount of beta-glucans and their spatial accessibility determine much of the binding efficiency of ZEA and OTA.

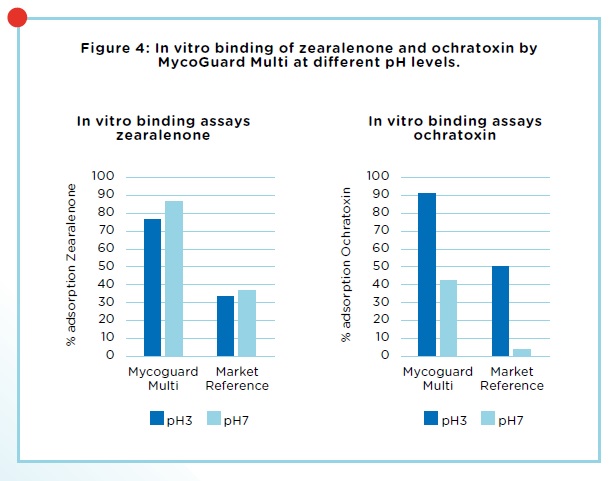

In-vitro screening trials were conducted with different YCWs to select a strain that would best match the required binding of ZEA and OTA. From this screening YCW strain 2 stood out as an efficient binder of ZEA and OTA mycotoxins (see fig. 3). YCW from this specific strain was selected for further in-vitro and in-vivo testing. MycoGuard Multi is a combination of the most effective bentonite clays and the best binding YCW, resulting in a very effective de-activation of AFLA, ZEA, and OTA as illustrated in figure 4.

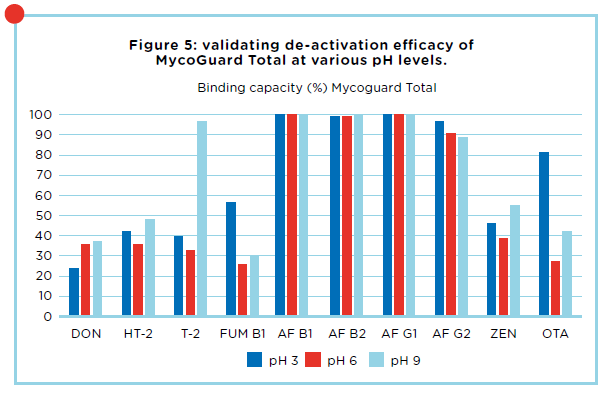

De-activating fumonisin and trichothecenes

Options for mitigating the negative effects caused by fursarium mycotoxins, such as Fumonisin and Trichothecenes (including DON, T-2 and HT-2), are mainly limited to the enzymatic bio-transformation into non- or less toxic metabolites. To enable the de-activation of a broad spectrum of mycotoxins, MycoGuard Total was designed, combining bentonite clays and the YCWs with selected enzymes as deactivation methods to provide the most complete protection against mycotoxins. In vitro trials were conducted at the University of Gent, testing the bio-transforming and binding capacity of Mycoguard Total against commonly found mycotoxins under various conditions frequently found in animal feeds.

Performance under in vivo conditions

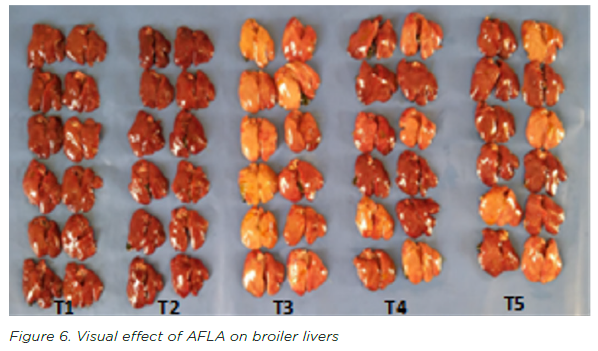

The final and very important validation of the MycoGuard assortment is in the form of in-vivo trials. In vivo trials were conducted at Samitec and looked at the mitigating effects of Mycoguard Focus and Mycoguard Total in broilers challenged with AFLA and FUM respectively. The setup was similar for both trials. Two negative controls (one without (T1) and one with Mycoguard (T2)) were compared to a positive control with only AFLA or FUM (T3), and two groups with AFLA or FUM with two inclusions of Mycoguard (T4 and T5). During the first trial, significant improvements were achieved in zootechnical performance when Mycoguard Focus was added to feeds contaminated with AFLA. A visual comparison was also made of randomly selected livers from the different treatment groups. The negative effect of AFLA on the livers can be clearly seen in the livers of T3 (see figure 6). Equally visible is how in T4 and T5 Mycoguard Focus can help prevent the negative effects of such a high level of intoxication under in-vivo conditions.

A second trial, as described previously, looked at the mitigating effects of Mycoguard Total in broilers challenged with FUM. Here too, there was a significant improvement in zootechnical performance when Mycoguard Total was added to the challenge groups. A known biomarker in animals indicating the presence of FUM in feed is the SA:SO ratio (sphinganine:sphingosine). An increase in this ratio signifies a disruption in the formation of sphigolipids, essential for many functions at a cellular level. FUM caused a significant increase (T3) in the SA:SO ratio which was clearly reduced when Mycoguard Total was added (T4 and T5) to the feeds.

Get expert advice

Our specialists can advise and support you to determine the right approach for your specific situation. By recommending a combination of optimal farming practises and the right application of MycoGuard products, you can maximise animal production and financial performance. Visit our Mycoguard for more information about the Mycoguardproduct range.